This week we covered concepts related to operations management and supply chain management.

In today’s competitive market, businesses rely heavily on both Operations Management (OM) and Supply Chain Management (SCM) to maintain efficiency and meet customer demands. OM is the business function responsible for planning, coordinating, and controlling resources needed to produce products, technology, and services for a company. It involves leveraging technology, ensuring quality, maintaining productivity, forecasting demand, managing capacity, and addressing key concerns like customer service, supplier relations, staffing, and scheduling (Kennedy, 2019).

On the other hand, SCM focuses on managing the flow of materials from suppliers to customers, aiming to minimize costs and improve responsiveness. This includes procurement, production, distribution, and logistics. Companies operate in different e-commerce models, such as B2B (business-to-business), B2C (business-to-consumer), and C2C (consumer-to-consumer), each requiring strategic supply chain operations to optimize efficiency (Kennedy, 2019). With SCM, companies can cut excess costs and deliver products to the consumer faster and more efficiently. A supply chain manager is typically tasked with controlling and reducing costs and avoiding supply shortages while focusing on the five most critical phases of SCM, which are planning, sourcing, production, distribution, and returns (Fernando, 2024).

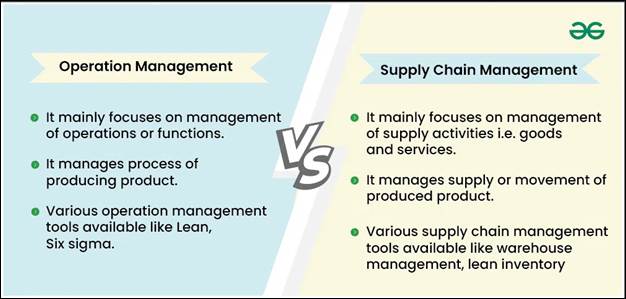

The differences between OM and SCM can be thought of as follows (GeeksforGeeks, 2024):

There are several areas where SCM and OM functions can overlap (Altexsoft Editorial Team, 2023):

SCM is in charge of external interactions with suppliers, warehouses, distributors, and end-customers, while OM supervises everything that happens internal to the company. Large organizations usually split responsibilities between two executives — a supply chain manager and an operations manager, although small companies often don’t separate the external and internal parts of product flow.

By integrating OM and SCM, businesses can ensure streamlined processes, reduced waste, and improved customer satisfaction, reinforcing their market position. The use of automation, artificial intelligence, and predictive analytics further enhances operational efficiency, allowing organizations to adapt to market changes and consumer expectations (Drickhamer, 2004).

References:

Altexsoft Editorial Team. (2023, September 26). Supply chain management (SCM) software, process, and roles. Altexsoft. https://www.altexsoft.com/blog/supply-chain-management-software/

Drickhamer, D. (2004, December 21). A leg up on mass customization. IndustryWeek. https://www.industryweek.com/leadership/companies-executives/article/21953132/a-leg-up-on-mass-customization

Fernando, J. (2024, June 27). Supply chain management (SCM): How it works & why it’s important. Investopedia. https://www.investopedia.com/terms/s/scm.asp

GeeksforGeeks. (2024, September 20). Difference between operation management and supply chain management. https://www.geeksforgeeks.org/difference-between-operation-management-and-supply-chain-management/

Kennedy, C. (2019, August 5). Operations management introduction [Video]. YouTube. https://www.youtube.com/watch?v=rdeA3UCp2OY

Leave a comment